The Carbon Neutrality Commitment/Pathway to Achieve Carbon Neutrality during the construction period

Technological Innovation

The construction industry has a long history and pursues exquisite craftsmanship, and technological innovation has always been one of the most important factors in the process of development. With the changes in the global social structure and the rapid development of information exchange capabilities, the construction industry, which is characterized by dust and labour intensive in the traditional impression, is gradually moving towards the direction of intelligent construction, and the extensive use of new technologies also brings about a profound change to the construction industry. Over the years, CSHK has been investing resources to develop smart construction sites and leading its staff and partners to enter the era of the construction industry 2.0.

In the process of innovation, we focus on the integration of construction experience and technological innovation, bringing together the wisdom of all parties, and promoting the application of new technologies such as MiC and BIM throughout life cycle of buildings, thereby realizing the value brought by technology. At the same time, we also apply innovative technologies in design and construction to achieve green and environmentally friendly construction practices. The specific emissions reduction measures and implementation plans are as follows:

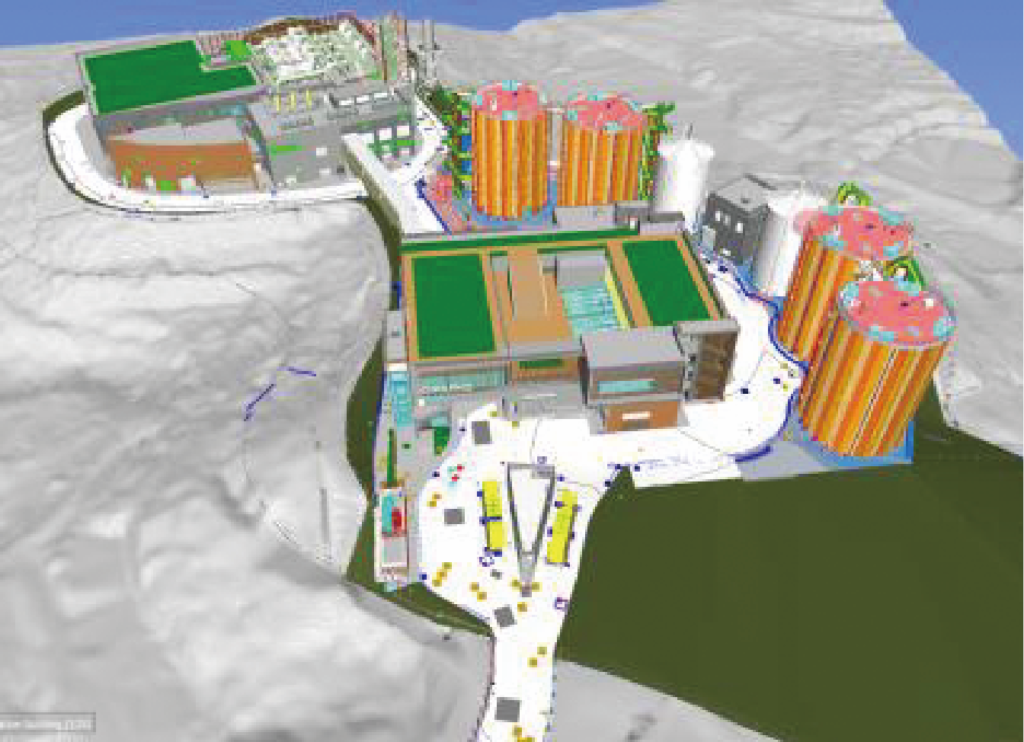

1. 7D BIM-embedded construction life cycle management system and innovative technology platform

We have adopted the BIM technology on the construction aspect, such as using 3D model guidance to complete crash check, 4D model guidance to smoothen construction processes, and 6D model guidance for operation, in order to clarify all equipment information. The high level of definition is rare in Hong Kong construction work and serves as a practical example for CSHK to lead the industry towards high efficiency management and development. The project has also explored the use of BIM 7D to connect the model to CIC’s Carbon Assessment Tool to streamline the carbon assessment process.

2. Adoption of DfMA and MiC

The O⬝PARK2 Project has demonstrated the uses of MIC Technology to build site office, of which 70% of the construction process was completed in the Mainland factories, and the components were sent to Hong Kong for assembly, which significantly reduced the construction time, thereby reducing the disturbance and pollution of the site construction, and improving the quality of the project. The office can be dismantled and recycled after the work is completed. In addition, the construction of part of the works will also adopt the DfMA building method to further reduce the carbon footprint of the construction works.

Based on the internal estimation of CSHK, as compared to the traditional construction method, MiC technology could help to reduce 80% of timber consumption, avoid 60% of noise and construction waste generation and reduce human resources by 50%.

3. Introduction of innovative materials

We adopted fibre or iron modified cement, inlaid high-density protective layer and other advanced materials and technologies for anti-corrosion protection to ensure procedures of processing food waste achieve the effects of acid resistance, high temperature, anti-aging, anti-wear, and further extends the machine’s longevity and achieve sustainability.