The Carbon Neutrality Commitment/Pathway to Achieve Carbon Neutrality during the construction period

Sustainable Management

CSHK adheres to the commitment of construction compliance and pursues the concept of green development based on stable and solid management. At the same time, in order to reduce the carbon emissions from construction projects, we also strive to prioritize procurement in close proximity and of environmentally friendly materials in supply chain management. This not only aligns with the United Nations’ sustainability goal, “Responsible Consumption and Production”, but also help to encourage business partners to follow the sustainable development approach. The specific sustainable management directions are as follows:

1. Enhance the disclosure of carbon-related information

CSHK has disclosed its sustainability performance to the public through its sustainability report since 2019. The research results of the O⬝PARK2 project will then be shared with the public through the project website and sustainability report in the hope of contributing to the low-carbon transformation of the construction industry.

In addition, in order to digitalize the carbon quantification process, we have independently developed the Carbon Neutrality E-platform (“E-platform”) for collecting and demonstrating the carbon emissions level of the O⬝PARK2 project. Developed based on the Group’s internal sustainability data cloud platform, the E-platform achieves internal information integration, greatly reduces the difficulty of collecting carbon emissions related data at construction sites and offices, and increases the accuracy of data. The E-platform updates the quantity and distribution of greenhouse gas emissions and the effectiveness of carbon reduction measures at the construction site and office monthly; provides a dynamic display using carbon dioxide equivalent as the unit to help decision-makers to control the Group’s real-time carbon emissions information, and to formulate corresponding countermeasures as well as to build the foundation for future carbon asset development, trading and management.

2. Active participation in sustainable development related design and construction projects

O⬝PARK2 project adopts the DBO model (design, construction and operation)

Hong Kong produces approximately 3,353 tonnes of food waste per day, which not only places tremendous pressure on Hong Kong’s landfills, but also generates landfill gas and leachate, affecting the surrounding environment. Therefore, the Hong Kong Government has planned to build O⬝PARK2 at the former Sha Ling Livestock Waste Control Centre in North District, covering 2.5 hectares of land. The hosting right of the project was awarded to AJA Joint Venture which is formed by CSHK jointly with Jardine Engineering Corporation and UK Agrivert Ltd. The operating duration is 15 years and is estimated to start in 2023. After the completion of the project, the project is expected to avoid the emission of approximately 67 thousand tonnes of greenhouse gases and reduce the disposal of approximately 0.11 million tonnes of food waste to landfills every year, thereby safeguarding Hong Kong’s environment and natural resources.

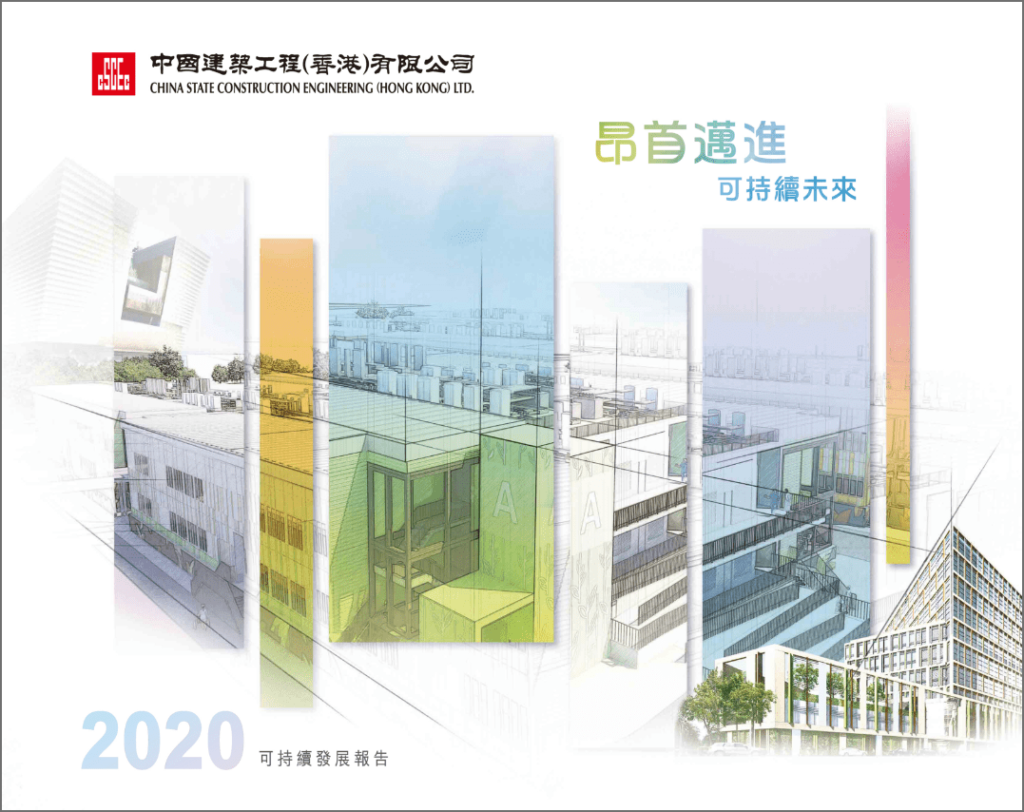

With the government’s original planned daily waste processing capacity of 300 metric tons/day, the project members successfully increased the processing capacity to 600 metric tons/day through the refined BIM design without changing the land use area. In addition, in the process of design and construction, 40% of the original plants are retained on the construction site, and the cut-down trees will also be re-planted within the area of the construction site. In order to increase the greening area to 50%, the construction site has also designed a rooftop garden and an urban farm on the building to integrate the building into the surrounding environment.

3. Smart Site Integrated Management

O⬝PARK2 adapted the C-Smart intelligent construction site management platform, which has been independently developed by Transcendence Company Limited., a wholly-owned subsidiary of CSHK. The platform achieves digitalized, refined, and intelligent management while reducing carbon emissions in the daily management of the construction site. Based on the self-developed technologies such as facial recognition, Internet of Things and artificial intelligence, C-Smart collects and automatically consolidates site information into an integrated information management platform. The platform collects and analyzes site information, assists construction management and decision-making, and comprehensively manages the personnel, safety and environmental protection, progress, materials, and other aspects of construction projects to achieve intelligent monitoring and management.

• The C-SMART safety helmet is equipped with an automatic punch infunction, which enables the management to know the real-time number of personnel in each part of the site. Under the pandemic, if there are site workers being diagnosed, the system can quickly track the employees who have been in close contact with the confirmed case through its function and cut off the infection chain as soon as possible.

• The C-SMART license plate automatic identification system only allows registered vehicles to enter the site area, which increases site safety.

• The C-SMART AI monitoring system is capable of automatic smoke detection, fire alarm initiation and can evacuate site staff quickly in the case of a fire emergency.

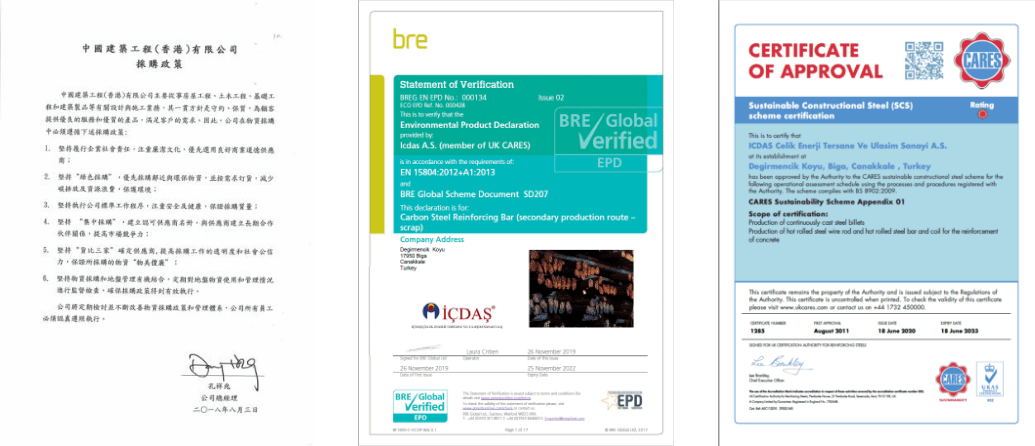

4. Supply Chain Management

CSHK has stated its requirements on green procurement in its Procurement Policy and Supplier’s Code of Conduct, prioritized procurement in close proximity and of environmentally friendly materials as well as ordering goods on demand, and in strict accordance with the quantity of requested by construction sites and project needs, in order to reduce carbon emissions and waste of resources. Based on green procurement, O⬝PARK2 will further use low-carbon construction materials available on the market, giving priority to rebar with 100% recycled content, H-beam steel, and concrete with more than 35% fly ash as replacement for cement, thus greatly reduce the project’s embodied carbon emissions.

5. Site Environmental Management

The site environmental objectives set by O⬝PARK2 include:

Water conservation:

Using a well-established sewage treatment system to properly treat construction sewage during the construction period. A portion of the water recycled at the site is used for cleaning of the vehicles, which can save about 36,500 litres of water annually. The currently installed Falcon Waterfree Urinals in the toilets on site can save up to 151,000 litres of water per year. After the project is completed, the sewage treatment system will provide 294.5 m3 of reclaimed water for daily cleaning and process water in the plant; Rainwater is collected and the treated wastewater is recycled for plant irrigation, which can save 82.4% of irrigation water.

Energy saving:

Use energy-saving appliances and equipment, set up energy-saving reminders and lighting with motion sensor in the site office; install and use sustainable energy facilities. Solar panels will be installed, and Smart Electricity will be used to monitor daily power consumption as well as solar power generation in Reception Building upon completion.

Resources conservation:

Replacing timber formwork with recyclable formwork. Due to the characteristics of DBO project, BIM was used to further optimize the structure design of anaerobic digesters, which reduced the use of concrete by 22.5%, and the concrete and steel bars used were produced with recycled materials, of which the proportion of steel bar regeneration was up to 100%. Smart site reduced most of the office paper consumption at construction sites.

Construction site electrification:

The site has tested and replaced a conventional generator with CLPe Battery Energy Storage System (BESS) in September. In addition, 4 electric vehicles were purchased for the site to improve roadside air quality and reduce greenhouse gas emissions.

Waste disposal:

Promote paperless meetings and inspections to reduce the use of paper and related waste. Turning waste materials back into resources; from the date of commencement of the construction site to August 2021, a total of 8,750 tonnes of inert construction waste were seperated, recycled at the source, sent to fill bank and temporary construction waste sorting facility respectively to provide an economic source of fill for reclamation; 37 tonnes of non-inert construction waste were sent to EcoPark for recycling and 375 tons of waste including iron, plastic, paper and glass were recycled through Fanling Recycling Store of the new Environmental Protection Department community recycling network., namely GREEN @ COMMUNITY. Over 94% of the waste generated on site has been recycled to date, with a total of 9,162 tonnes recycled so far. The site has also been equipped with solar-powered smart bins, which use solar panels to generate electricity to compress up to 300kg of waste.

CSHK requires each site to prepare and follow an environmental management plan, and reviews regularly to ensure the implementation of these plans ; At the same time, CSHK promotes effective use of resources while reducing construction waste though optimizing construction designs, processes, and material management. To date, all sites have obtained ISO 14001: 2015 environmental management system certification. At present, each site will also set up a comprehensive site management working group according to the actual situation, and the site manager will be the person in charge, fully responsible for the environmental protection work of the site.